Rescue your infernal cylinder head

1. Cleaning Machine

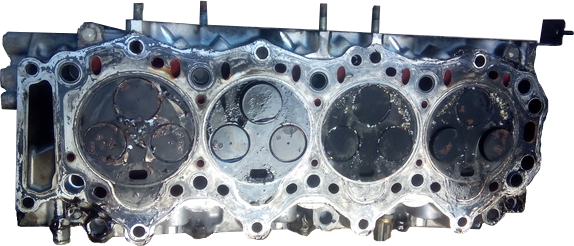

The cylinder head is first placed into our specialist cleaning machine, which removes oil, carbon deposits, gasket residue and contaminants. This allows us to inspect the head properly and ensures accurate testing and machining.

2. Pressure Tester

Once cleaned, the cylinder head is pressure tested to check for cracks or internal leaks that may not be visible to the naked eye. This step is crucial, especially on modern engines, as even a small unseen fault can cause future failure. If a fault is found, we’ll advise you before any further work is carried out.

3. Head Skimmer

If the cylinder head surface is found to be uneven or warped, it is precision skimmed using a specialist head skimming machine. This restores the surface to the correct flatness, allowing the new gasket to seal correctly and helping prevent repeat issues. Only the minimum material required is removed to stay within manufacturer tolerances.

RESTORE SEALING SURFACE AFTER GASKET FAILURE

ENSURE A PERFECT FIT BETWEEN HEAD AND ENGINE BLOCK

IMPROVE COMPRESSION

PREVENT FUTURE HEAD GASKET LEAKS

IMPROVE ENGINE PERFORMANCE

EXTEND ENGINE LIFE